Solar

Low Temperature Curing Silver paste for HJT Solar Cell

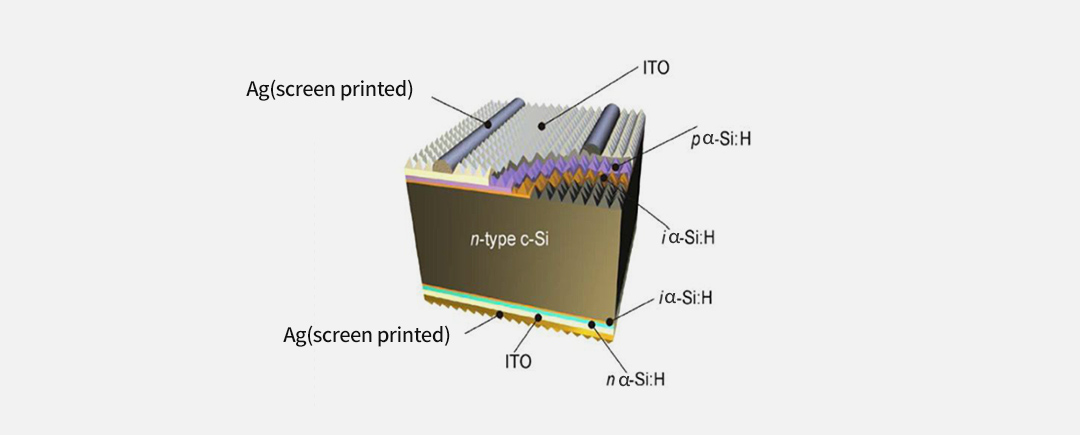

Hetero Junction with Intrinsic Thin Layer(HJT) Cell

This cell has α-Si: H thin film bonded to the front and rear surfaces with low temperature by using n-type crystalline silicon.

Ag Paste for low temperature (200℃) firing for HJT

Low-temperature firing process is very advantageous for thinning of wafer because the possibility of damage on cell is low due to low thermal stress during cell fabrication below 300℃.

On the other hand, the α-Si: H thin film is damaged during the manufacturing process in high-temperature firing process, so the conventional high temperature silver paste cannot be used.

Hardening condition - 150℃/10min : Drying, 200℃/30min : Thermosetting, Resistivity ≤8 X 10-6Ω·㎝

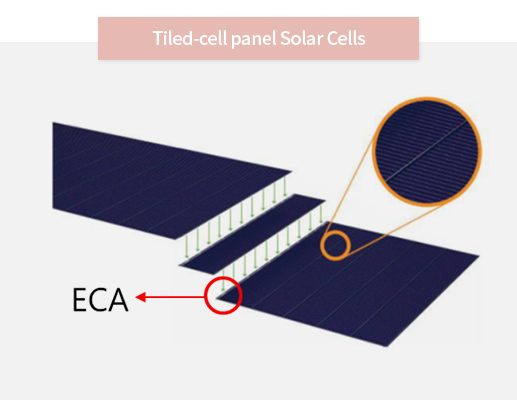

ECA for Shingled Solar Module

ECA is a conductive adhesive, composed of conductive particles and a binder.

ECA can be reworked according to the type and does not use lead (Pb) during the bonding process.

The stress caused by heat is lowered by replacing the conventional ribbon soldering method in the solar cell module,

Hardening condition - 150℃/10sec , Resistivity < 8×10-5Ω·㎝

Products List – Conductive / Non-conductive Coating adhesive

| Model | Binder | Hardening condition | Volume resistance(Ω·cm) | Filler | Viscosity (cps) | Features |

|---|---|---|---|---|---|---|

| EG-CA-0515 | Epoxy | 130℃ / 1hr 150℃ / 20min |

<1 x 10-4 at 130℃/1hr | Ag | 30,000 | Tg > 120℃ at 130℃ curing |

| EG-CA-1015 | Epoxy | 150℃ / 1hr | <5 x 10-4 | Ag | 56,000 | For Die attachment |

| EG-CA-9215E | Epoxy | 150℃ / 30min | <5 x 10-4 | Ag | 116,000 | For Die attachment |

| EG-CA-0975M | Epoxy | 175℃ / 1hr | <1 x 10-4 | Ag | 16,000 | For Die attachment |

| EG-CA-3015 | Epoxy | 150℃ / 2hr | <4 x 10-4 | Ag | 16,000 | For Die attachment |

| Model | Binder | Hardening condition | Volume resistance(Ω·cm) | Filler | Viscosity (cps) | Features |

|---|---|---|---|---|---|---|

| EG-UA-1160 | Epoxy | UV > 1,600mJ/㎠ Heat > 120℃ / 30min |

Silica | 75,000 | Optical Connector | |

| EG-UP-013 | Acrylate/Epoxy | UV > 2,000mJ/㎠ | Ag | 49,000 | UV conductive adhesive 10mm X 10mm X 15um < 1Ω | |

| EG-UI-010 | Epoxy | UV > 1,500mJ/㎠ | 20,000 | UV curable Insulation | ||

| EG-UA-202V | Acrylate | UV > 500mJ/㎠ | colorant | 20,000 | Violet, WVTR 6.3g/㎡,25℃/24hr | |

| EG-UA-201B | Acrylate | UV > 2,000mJ/㎠ | Black(non-carbon) | 20,000 | Display sealant, WVTR 54g/㎡ at 60℃/90%/24hr | |

| EG-UA-2100 | Epoxy | UV > 300mJ/㎠ | Silica | 10,000 | 6H hardness | |

| EG-UA-3100 | Epoxy | UV > 150mJ/㎠ | 5,000 | Polyolefin adhesion, Medical application | ||

| EG-UA-3200 | Acrylate | UV > 150mJ/㎠ | 6,000 | PET/PMMA bonding, Medical application | ||

| EG-UA-3202 | Acrylate | UV > 150mJ/㎠ | Silica | 10,000 | Low CTE < 40ppm | |

| EG-UA-2105 | Epoxy | UV > 2,500mJ/㎠ | Silica | 180,000 | Low CTE < 30ppm | |

| EG-B-EA04 | Epoxy | Heat > 150℃/20min | Silica | 30,000 | Underfill | |

| EG-B-EA06 | Epoxy | Heat > 130℃/5min | Silica | 20,000 | Short Curing Time |

EG Chem

Head Office and Gongju Plant33-26, Tancheonsaneopdanji-gil, Tancheon-myeon, Gongju-si, Chungcheongnam-do | Tel : +82-41-857-5984 | Fax : +82-41-857-5986

Hwaseong Laboratory30, Seja-ro, Jeongnam-myeon, Hwaseong-si, Gyeonggi-do | Tel : +82-31-8077-4986 | Fax : +82-31-8077-4985

Hwaseong Branch32, Seja-ro, Jeongnam-myeon, Hwaseong-si, Gyeonggi-do | Tel : +82-31-8077-4992 | Fax : +82-31-8077-4993

© 2018 EG Chem . All Rights Reserved | Design by Threeway